Innovative Kingdom of Paint & Print Solutions

Explore India’s top service for Spray painting, Hydrographic Painting & Digital Printing providers.

Our Services

Download Our Product E-Catalogue

Explore our range of coating services across various industries

Get an exclusive insight into the world of paint and print solutions. Download Paint King’s e-catalogue to explore our range of spray painting & hydrographic solutions to elevate the aesthetics of your product.

Why Choose Us?

For over 30 years, we’ve been the leading experts in Spray painting, Hydrographic painting, Digital Printing and Injection Molding. Our experience translates to exceptional quality, innovative techniques, and solutions that bring your ideas to life. Choose us, and get it done right, the first time.

Years of Industry Expertise

Locations

Team Members

Per Day Production Capacity

Our Expertise

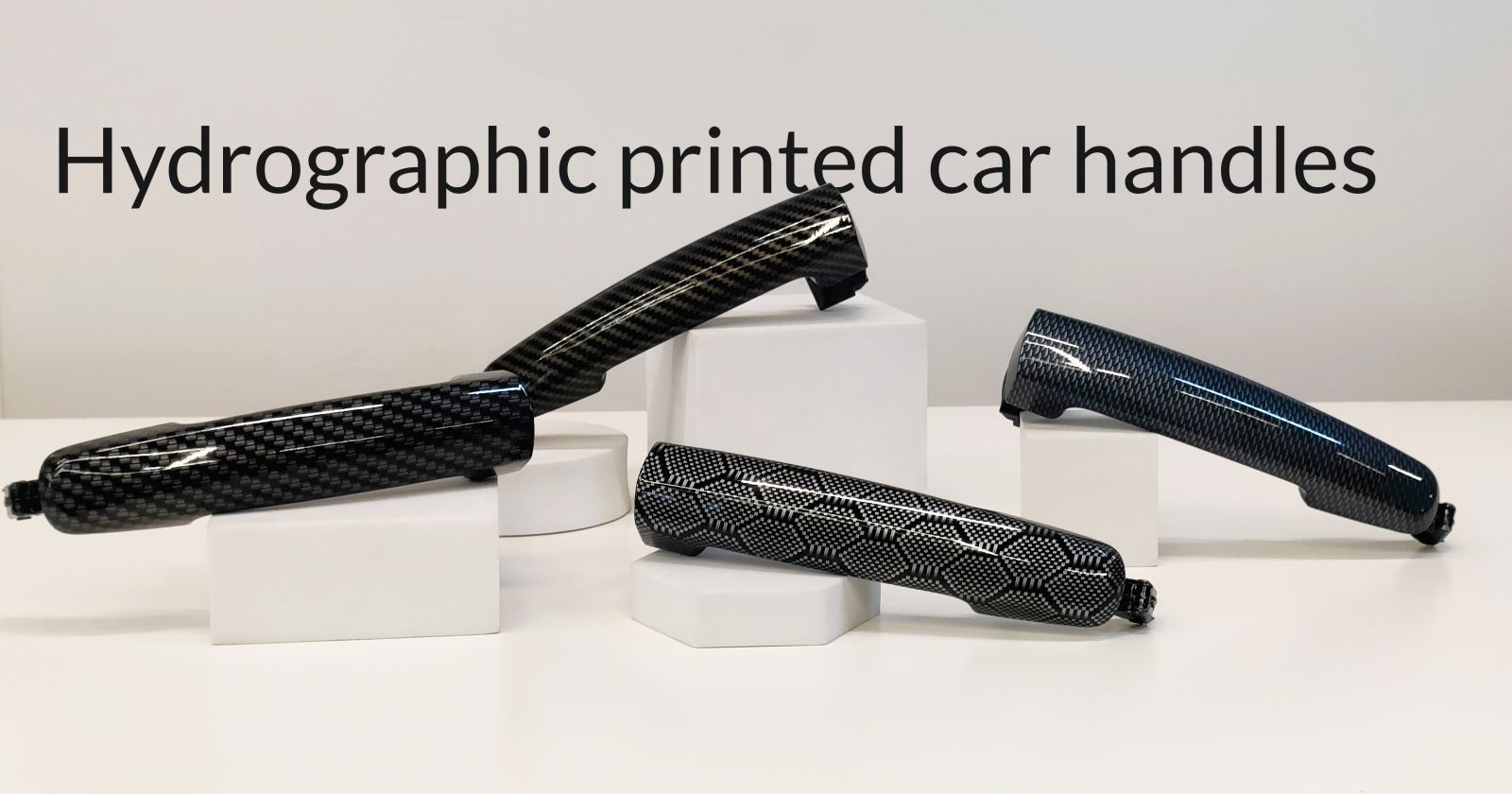

Stand out of crowd

With the help of premium spray painting & hydrographic printing solutions, make sure your products stand out of the crowd and have a distinctive edge.

Top notch quality

Every product that leaves our premises undergoes a strict quality check. Our spray painted and hydrographic coatings ensure a seamless and premium finish even in bulk quantities.

Massive production

Our massive production capacity and skilled workforce ensures every spray painted product looks flawless even in bulk quantities.

Latest technology

With regular research and development, we are able to transform products with the help of latest spray painting and hydrographic printing technologies. Our design team regularly experiments to deliver the latest trends.

Our Clients

Our list of clients includes industry leaders, top MNCs as well as budding entrepreneurs & designers who wish to transform their products with the help of our premium spray painting and hydrographic printing service. Explore the transformative impact our partnership can have on your business.

Testimonials