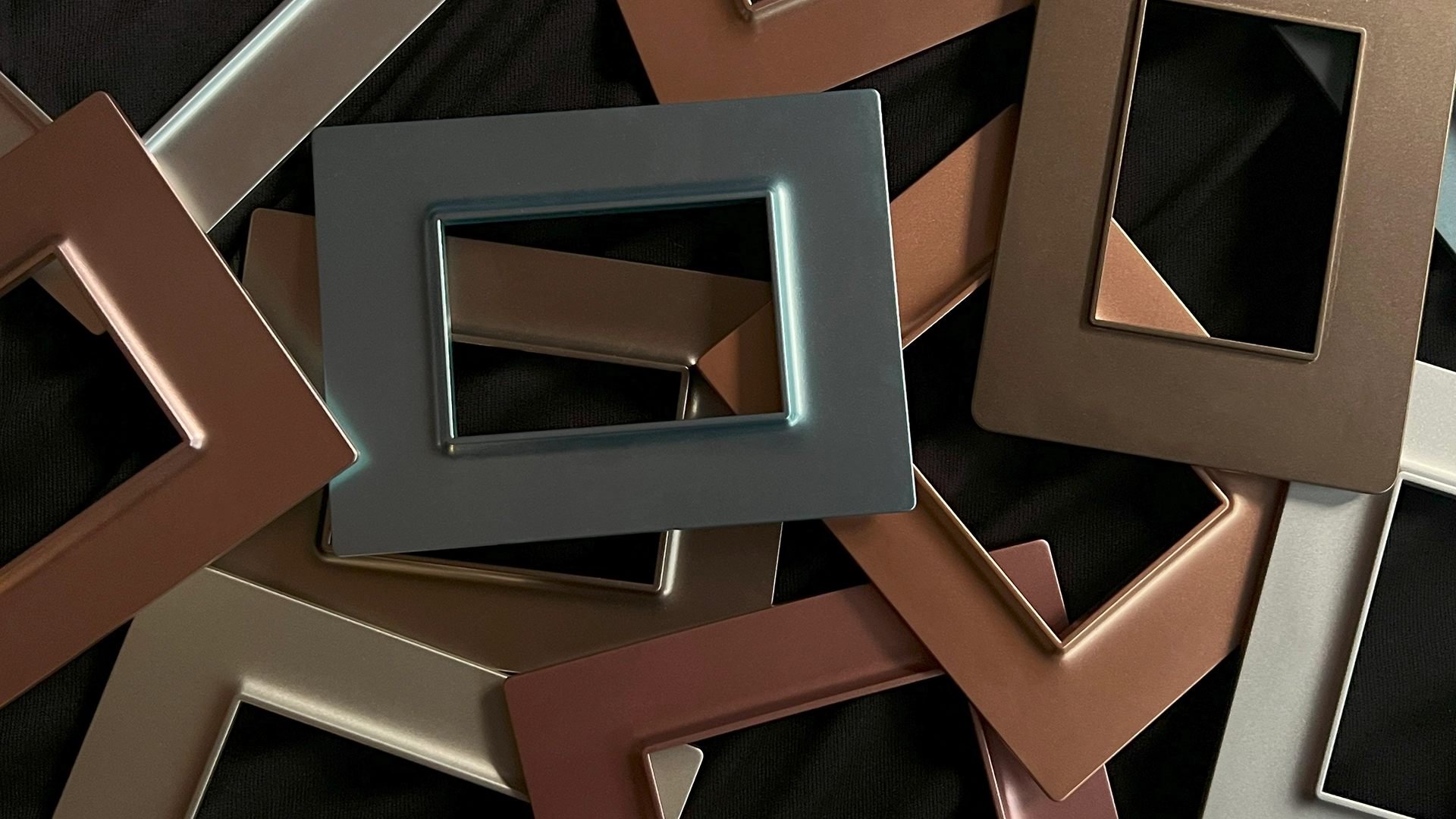

Transforming metals and plastics with advanced spray painting in Mumbai, Haridwar, Vapi, and Vasai

At Paintking, we offer spray painting services in Mumbai, Haridwar, Vapi and Vasai. With over 30 years of experience, our team uses specialized machinery to produce stunning paint applications on metals, plastics, auto parts and more. Our work delivers a strong and beautiful finish—perfect for business, industry and household items. Paintking delivers experience, quality, and trust in every job.

Service Overview

Spray painting is a cleanest and fastest way to paint. In this, the paint is converted into a very fine spray by air pressure and sprayed on the surface in thin layers with a spray gun. There are no brush marks, the color reaches the corners easily, and the finish looks even and smooth. With the right distance, the right nozzle and 2-3 thin coats, the paint dries quickly, has a strong grip and gives great results on everything – metal, plastic or intricate shapes.

At Paintking, we offer specialized spray painting services on metal, plastic and auto parts. We have advanced machinery that ensures smooth, strong and uniform coating. Spray painting gives an attractive paint finish on surfaces with speed, durability and high quality. The process is cost and time saving. With a wide production capacity in Mumbai, Haridwar, Vapi and Vasai, Paintking is a reliable and efficient solution for your business, industrial and household products.

Spray Painting Finishes & Effects

Before and After

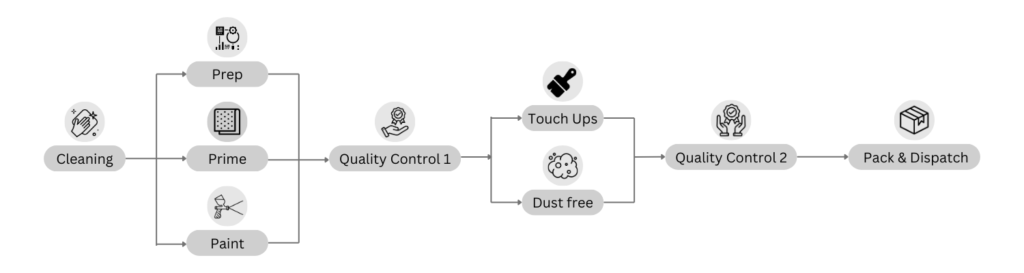

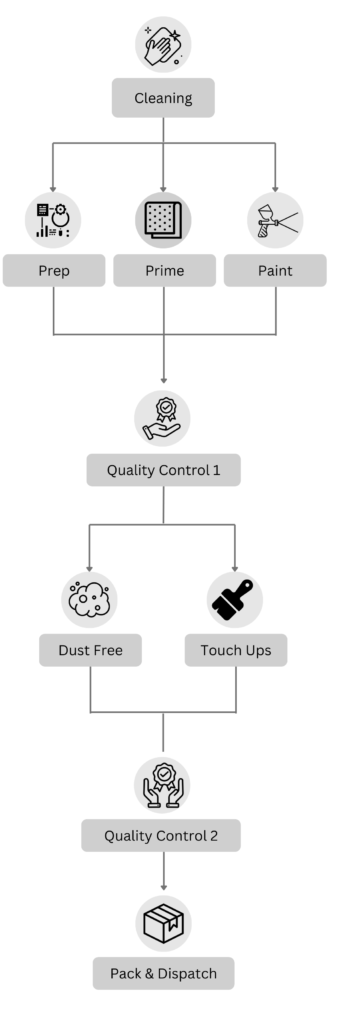

Our Spray Painting Process

Industries & Use Cases

- ABS/PC trims, bezels, switch frames

- Matte, metallic, soft‑feel finishes

- Uniform film build, ΔE control

- Faceplates, enclosures (ABS/PC)

- Dust‑free booths, color match

- Texture, satin, pastel shades

- Knobs, handles, fascia (CRCA/ABS)

- Anti‑scratch, uniform gloss

- Batch repeatability

- Bottles, caps, accessories

- Pastel, two‑tone, texture

- High visual appeal

- Handles, brackets, profiles

- Antique, brass, woodgrain

- Durable coatings

- Panels, covers, housings

- CRCA/FRP/steel/aluminum

- Corrosion resistance

Quality Assurance & Safety Standards

1. What we assure

- Four‑stage checks: Incoming, In‑Process, Final, and Pre‑Dispatch so every lot is verified end‑to‑end.

- AQL‑based sampling, batch traceability, master‑shade and draw‑down cards maintained.

2. Color accuracy (spectrophotometer)

- Each batch is measured on a spectrophotometer; only lots within the agreed ΔE tolerance are released.

- Color recipes and approvals are logged for repeatable re‑orders.

3. Finish and adhesion tests

- Gloss meter readings at specified angles for uniform appearance.

- Visual inspection for dust, runs/sags, orange‑peel, pin‑holes under task lighting.

- Tape/cross‑hatch adhesion tests, dry‑film‑thickness (DFT) gauge checks, and cure time verification.

4. Process control

- Booth logs for temperature/humidity, airflow/filtration, paint viscosity, and gun settings.

- Scheduled calibration of spectro, gloss meter, DFT gauge; NCR‑CAPA with root‑cause analysis.

Benefits of Spray Painting

Spray painting provides an even and beautiful coating on any surface. It also gives a consistent finish, even on corners, curved surfaces and fine mesh. Spray paint can be applied quickly and cleanly in very thin layers, without any brush marks. The result is strong, durable paint that is resistant to weather, dust or scratches. This keeps objects looking fresh and bright for a long time.

Spray painting not only looks good, it is also more efficient. It uses less paint, saves time and can get the job done quickly, even on a large scale. Machine-based application provides consistent color, consistent thickness and complete control that is, consistent quality every time.

Compared to traditional brush or roller methods, spray painting does not leave marks, does not require rework and reaches hidden areas easily. This is the reason why spray painting has become the most preferred method nowadays for many products like vehicles, machines, furniture and electronics.

Frequently Asked Questions (FAQ)

1. How much does spray painting cost?

Spray painting costs depend on part size, finish type, quantity, and complexity. We provide detailed quotes based on your specific requirements including surface area, desired finish, and turnaround time.

2. What factors affect the pricing of spray painting services?

Key factors include surface preparation required, type of material (ABS, metal, etc.), finish complexity (matte, metallic, texture), quantity of parts, and any special requirements like masking or color matching.

3. Is spray painting more expensive than brush painting?

While initial setup costs may be higher, spray painting is often more cost-effective for larger volumes due to faster application, better coverage, and reduced labor time.

4. Do you charge extra for color matching?

Yes, precise color matching using spectrophotometer requires additional setup and testing. We provide color match samples for approval before production.

1. What materials can be spray painted?

We spray paint ABS, PC, PP, nylon, CRCA steel, stainless steel, aluminum, and other metals and plastics commonly used in automotive, electronics, and industrial applications.

2. How long does the spray painting process take?

Turnaround time depends on quantity and complexity. Small batches typically take 3-5 days, while larger production runs may require 1-2 weeks including drying and quality checks.

3. What surface preparation is required before spray painting?

Surfaces are cleaned, degreased, and may require sanding or etching. Plastic parts might need flame treatment, while metals may need primer application for optimal adhesion.

4. Do you provide primer application?

Yes, we apply appropriate primers based on substrate material to ensure proper adhesion, corrosion resistance, and optimal finish quality.

1. How long does spray painted finish last?

With proper preparation and quality materials, our spray painted finishes can last for years depending on environmental exposure and usage conditions.

2. What quality checks do you perform?

We perform color accuracy checks with spectrophotometer, gloss measurement, adhesion tape tests, and visual inspection under controlled lighting before dispatch.

3. Do you provide color consistency across batches?

Yes, we maintain color recipes and use spectrophotometer readings to ensure ΔE values stay within specified tolerances across different production batches.

4. What if the finished parts have defects?

We have a quality assurance process and will rework or replace parts that don’t meet agreed specifications at no additional cost.

1. What types of finishes do you offer?

We provide matte, satin, gloss, metallic, texture, soft-feel, wood grain, antique, and many specialized finishes to match your design requirements.

2. Can you match existing colors or provide custom colors?

Yes, we can match samples you provide using our spectrophotometer or create custom colors based on color codes, swatches, or your specifications.

3. Do you offer special effects like metallic or pearl finishes?

Yes, we specialize in metallic, pearl, color-changing, two-tone effects, and other decorative finishes commonly used in automotive and consumer product applications.

1. What is your minimum order quantity?

We handle both small prototype batches (as few as 10 pieces) and large production runs (thousands of pieces) depending on your project requirements.

2. Do you provide pickup and delivery services?

Yes, we can arrange pickup and delivery for local customers, or you can coordinate shipping for parts from other locations.

3. Can you handle rush orders?

Rush orders are possible. Contact us to discuss expedited timelines based on current workload and your urgency requirements.

1. Do you provide samples before full production?

Yes, we highly recommend sample approval for color, finish, and quality before proceeding with full production to ensure your expectations are met.

2. What documentation do you provide with finished parts?

We provide quality, color measurement reports, and batch tracking documentation as required for your quality systems.

3. Can you work with customer-supplied paint or specifications?

Yes, we can work with your specified paint systems or match to particular standards like automotive OEM requirements or industrial specifications.

4. Do you offer design consultation for finish selection?

Our team can advise on finish selection based on your application requirements, durability needs, and aesthetic goals to help you make the best choice.

5. What safety and environmental standards do you follow?

We maintain proper ventilation, waste disposal, operator safety protocols, and can provide RoHS/REACH compliance documentation when required.

Why Choose Paintking for Spray Painting

With 30+ years of hands-on experience, a skilled team and strict process control, Paintking assures consistent, premium spray finish every time. From prototypes to large production runs, we maintain the same process window, so colour, gloss and texture are consistent across batches and deliveries are on time.

Our quality system is built on measurable proof: colour-match (ΔE control) by spectrophotometer, gloss checks, adhesion/tape tests and DFT verification before dispatch. Also available are multiple finishes – such as matt, satin, metallic, soft-feel, textured, woodgrain, marble and antique – optimised for plastics (ABS, PC, PP, Nylon) and metals (CRCA, SS, Aluminium).

With high production capacity, clean SOPs and faster coordination, we reduce rework/rejects, control overall coating costs and improve the look-and-feel of the product. In short, choose Paintking—consistent quality time and again, fast turnaround and a finish that truly reflects your brand.

Download Our Product E-Catalogue

Explore our range of coating services across various industries

Get an exclusive insight into the world of paint and print solutions. Download Paint King’s e-catalogue to explore our range of spray painting & hydrographic solutions to elevate the aesthetics of your product.